1928 – 1932

Architects: Fritz Schupp, Martin Kremmer

Gelsenkirchener Straße 181, Essen, Germany

Zollverein Coal Mine, 1928-1932. Architects: Fritz Schupp, Martin Kremmer. Photo: Daniela Christmann

Zollverein Coal Mine, 1928-1932. Architects: Fritz Schupp, Martin Kremmer. Photo: Daniela Christmann

Zollverein Coal Mine, 1928-1932. Architects: Fritz Schupp, Martin Kremmer. Photo: Daniela Christmann

Site

The main area of the Zollverein Coal Mine with Shaft 12 and Shaft 1/2/8 is located in Stoppenberg in the northeastern part of the city of Essen, directly bordering the districts of Katernberg and Schonnebeck.

It is situated between the streets Gelsenkirchener Straße, Fritz-Schupp-Allee, Arendahls Wiese and Haldenstraße.

The main entrance with the prominent front view of the double trestle headframe is located on Gelsenkirchener Straße.

The Zollverein Coking Plant is located in the immediate vicinity between Arendahls Wiese, Köln-Mindener Straße and Großwesterkamp. The sites have been a World Heritage Site since 2001.

Foundation of the colliery

The colliery was founded by the industrialist Franz Haniel, who was looking for suitable coking coal deposits to produce the coke needed for steel production.

In 1834, he succeeded in penetrating the marl layer in Essen-Schönebeck for the first time. This laid the foundation for the Zollverein colliery.

Exploratory drilling in the Katernberg area discovered a particularly rich seam of coal, which was named after the German Zollverein, founded in 1833.

In 1847, Franz Haniel founded the Zollverein Mining Association and distributed the shares, known as Kuxe, among his family.

Haniel, who was co-owner of the Jacobi, Haniel & Huyssen smelting works (later Gutehoffnungshütte), planned to incorporate the Zollverein mine into the Sterkrader works. This would have made Zollverein the first steel mill in the Ruhr area. His plan failed due to the veto of the other shareholders of Hüttenunion Jacobi, Haniel & Huyssen.

The Cologne-Minden railroad, also opened in 1847, also played an important role in the choice of location. The line ran directly north of the colliery site, providing a good connection to the then new means of transportation, the railroad.

1920

From 1920, the Zollverein trade union, which until then had been owned by the Haniel industrial family, increasingly cooperated with Phönix AG für Bergbau und Hüttenbetrieb. The management of the colliery was placed entirely in the hands of Phönix AG and a syndicate was formed.

Under their management, renovation and repair work was carried out, shaft 2 was given a head frame and it was decided to renovate shaft 4/5. Shaft 11 was sunk in 1922 and completed in 1926. On the surface, shafts 4 and 11 were given identical headframes and the 4/5/11 open pits were renovated accordingly. At the same time the coking plant in shaft 4/5/11 was shut down.

With the takeover of Phönix AG by Vereinigte Stahlwerke AG in 1926, Zeche Zollverein was transferred to Gelsenkirchener Bergwerks-AG (GBAG) and became part of the Gelsenkirchen group. Under its management, the coking plants were gradually closed down.

Zollverein Coal Mine, 1928-1932. Architects: Fritz Schupp, Martin Kremmer. Photo: Daniela Christmann

1928 New construction of the shaft system

In 1928, GBAG began the construction of a completely new shaft system designed as a central conveyor system. With a production capacity of 12,000 tons of coal per day, Shaft 12 took over the entire coal production of the previous four installations with a total of eleven shafts. Architects Fritz Schupp and Martin Kremmer designed the mine, which was considered an architectural and technical masterpiece and set the standard for functional industrial construction. The mine was considered the most modern and beautiful colliery in the world.

The double-trestle headframe built in 1930 in solid wall construction became the model for many central winding systems built later. The shaft started production on February 1, 1932 and in 1937 it was named “Schacht Albert” (from 1941 “Schacht Albert Vögler”) after the then General Director of Gelsenkirchener Bergwerks-AG, Albert Vögler.

Zollverein Coal Mine, 1928-1932. Architects: Fritz Schupp, Martin Kremmer. Photo: Daniela Christmann

Zollverein Coal Mine, 1928-1932. Architects: Fritz Schupp, Martin Kremmer. Photo: Daniela Christmann

Zollverein Coal Mine, 1928-1932. Architects: Fritz Schupp, Martin Kremmer. Photo: Daniela Christmann

Central Pit 12

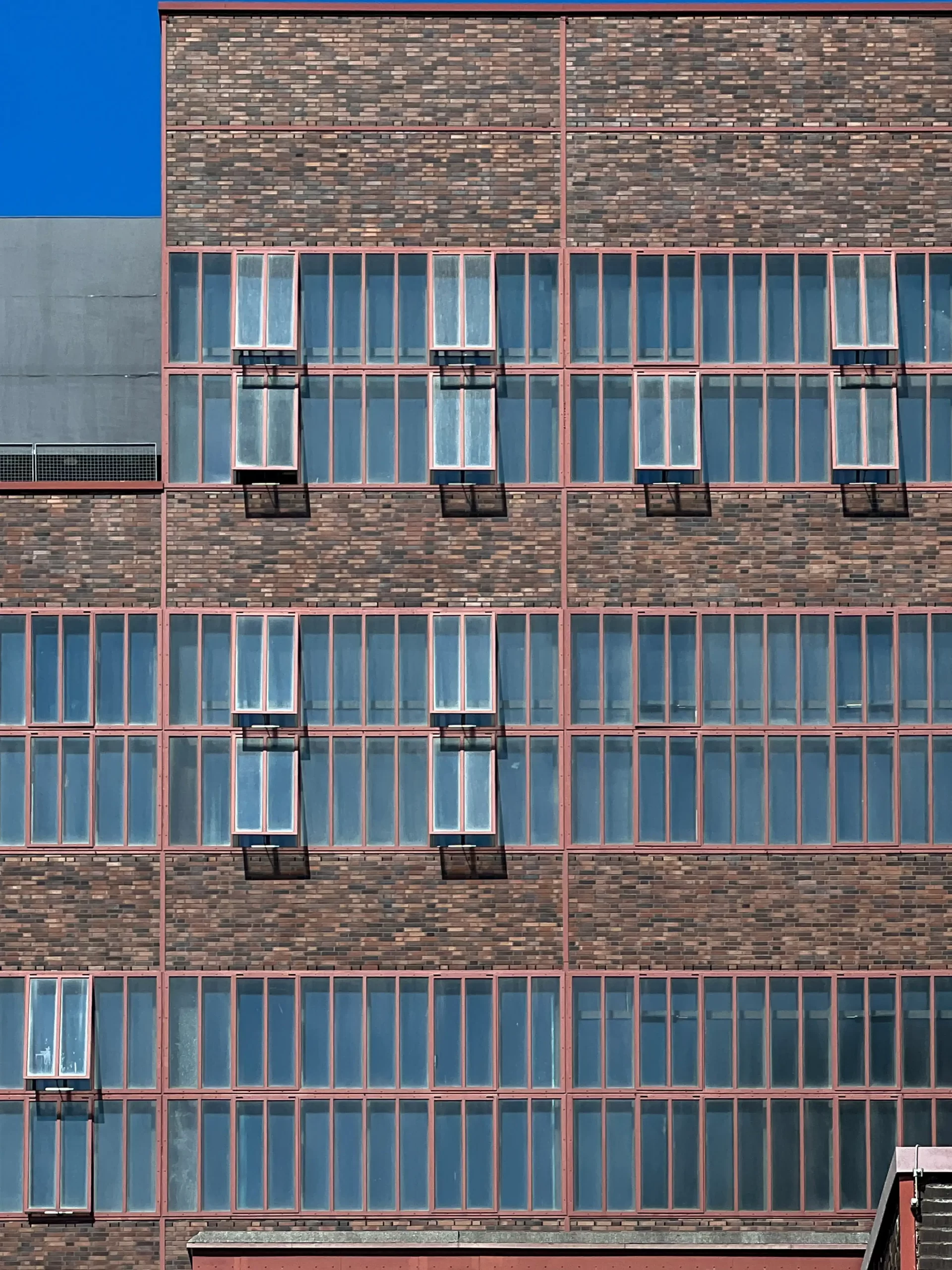

Central Pit 12 of the Zollverein complex in Essen is considered a major work of 20th century industrial architecture in Germany.

It was built between 1928 and 1932 to plans by architects Fritz Schupp and Martin Kremmer.

Free design of the facades was made possible by separating the interior structure from the exterior facade elements.

The steel-frame facades extend well beyond the load-bearing girders and terminate at the top with a U-profile.

Zollverein Coal Mine, 1928-1932. Architects: Fritz Schupp, Martin Kremmer. Photo: Daniela Christmann

Zollverein Coal Mine, 1928-1932. Architects: Fritz Schupp, Martin Kremmer. Photo: Daniela Christmann

The Axes

Designed by Fritz Schupp and Martin Kremmer between 1928 and 1932 and technically rebuilt between 1957 and 1958, the colliery complex is dominated by two intersecting axes with a lawn at their intersection.

The 55-meter-high headframe is the focal point of the main axis, which starts from Gelsenkirchener Straße and is initially defined by the short access road and two gatehouses of equal size.

The second axis, initially formed by two workshop buildings that form a narrow lane, is oriented toward the boiler house and has the 106-meter-high, unpreserved chimney as its focal point.

The design appeal of the complex lies in the uniform division of the facades, whose uniformity is reinforced by the grid of the steel framework.

Zollverein Coal Mine, 1928-1932. Architects: Fritz Schupp, Martin Kremmer. Photo: Daniela Christmann

Zollverein Coal Mine, 1928-1932. Architects: Fritz Schupp, Martin Kremmer. Photo: Daniela Christmann

Zollverein Coal Mine, 1928-1932. Architects: Fritz Schupp, Martin Kremmer. Photo: Daniela Christmann

Zollverein Coal Mine, 1928-1932. Architects: Fritz Schupp, Martin Kremmer. Photo: Daniela Christmann

Zollverein Coal Mine, 1928-1932. Architects: Fritz Schupp, Martin Kremmer. Photo: Daniela Christmann

Zollverein Coal Mine, 1928-1932. Architects: Fritz Schupp, Martin Kremmer. Photo: Daniela Christmann

Facades and compartments

All compartments are two meters high and rectangular in shape. Only the corner sections and, in some cases, the adjacent window sections are rectangular.

The Shaft Hall and Boiler House have vertical ribbon windows, presumably to emphasize the special position of these components in the main lines of sight.

In order to illuminate the larger halls for compressors, converters, conveyors and conveyor belts in the separation area, large window areas have been inserted in some of the facades.

The free design of the façade was made possible by the general separation of the internal primary construction and the external façade elements that close off the space. The primary structure consists entirely of double-hinged frames in solid wall construction, a type of construction that can also absorb horizontal forces from wind pressure. This reduced the number of transverse bracing diagonals or St. Andrew’s crosses, which would have obscured the open appearance of the interior and interfered with the arrangement of the windows.

In the case of double-shell walls with flat bars, the cross bracing, which cannot be dispensed with, has been integrated into the wall structure in such a way that it is not visible from either the inside or the outside. In the case of single-skin masonry, the St. Andrew’s crosses are placed under the roof surfaces so as not to disturb the division of the interior walls.

The opaque wire glass windows are flush with the facade, and the steel framing is painted the same color as the brick.

Zollverein Coal Mine, 1928-1932. Architects: Fritz Schupp, Martin Kremmer. Photo: Daniela Christmann

Lawns and driveways

The buildings in front of and beside the headframe are integrated into a system of lawns. The edging of the lawns consists of clinker set on edge as curbs. The driveways are paved with blue basalt stones and the walkways are paved with clinker stones. The lighting is provided by lanterns specially made for the shaft.

A network of narrow-gauge tracks embedded in the paving runs through the colliery’s paths. The tracks lead from the shaft to the various workshops and were used to transport the work pieces. A long footbridge spans the tracks that once led out of the sifting plant to the north of the reading room.

The bridge provided direct access to the Reading Conveyor Hall, the Mining Bunker and, via the connecting bridge, to Shaft 1/2/8.

Conveying capacity

The output of the Zollverein colliery increased enormously. In 1937 it reached 3.6 million tons with 6900 employees. The coking plant at shaft 1/2/8 had been reopened the previous year as a small new building with 54 coke ovens and produced 200,000 tons of coke per year. In 1937 the old two-story tower above Shaft 6 was replaced by a new two-story tower with a single hoist.

New construction after the world war

Zollverein survived the Second World War relatively unscathed. As early as 1953, an annual output of 2.4 million tons was achieved, making Zollverein once again the leading coal mine in West Germany.

After its incorporation into Rheinelbe Bergbau AG, the successor to the old GBAG, the operation of all the mines at Zollverein was extensively modernized and rationalized.

The headframe above Shaft 1 was replaced by a completely new structure in 1958. At the same time shafts 1/2/8 were completely rebuilt between 1960 and 1964 by the architect Fritz Schupp. In 1964 Shaft 2 received the headframe of Shaft 2 of the closed Friedlicher Nachbar colliery in Bochum-Linden as a new winding tower.

UNESCO World Heritage Site

Since 2001, the Zollverein Coal Mine and Coking Plant has been on the list of UNESCO World Heritage Sites in Germany.

After its closure in 1986, the state of North Rhine-Westphalia acquired the site of Shaft XII from Ruhrkohle AG, which was already a protected monument at the time of its closure.

The total area of Zeche Zollverein is the largest monument in the city of Essen.

In the years that followed, the site of Shaft XII was redeveloped. Bauhütte Zeche Zollverein Schacht XII GmbH ceased its remediation activities in 1999. From 1998 to 2008, the Entwicklungs-Gesellschaft Zollverein mbH (EGZ), the Zollverein Foundation and the Stiftung Industriedenkmalpflege und Geschichtskultur (Foundation for the Preservation of Industrial Monuments and Historical Culture) were responsible for the preservation and use of the disused facilities; since 2008, these tasks have been bundled in the Zollverein Foundation. On December 14, 2001, pits 12 and 1/2/8 and the Zollverein coking plant were inscribed on the UNESCO World Heritage List.

Between 2001 and 2002, architect Rem Koolhaas of OMA and landscape architect Henri Bava of Agence Ter developed a master plan for the transformation of the site into a vibrant cultural and business center.

Zeche Zollverein, 1928-1932. Architekten: Fritz Schupp, Martin Kremmer. Foto: Daniela Christmann

Zeche Zollverein, 1928-1932. Architekten: Fritz Schupp, Martin Kremmer. Foto: Daniela Christmann